Hello again, everyone,

In today's blog I will focus on the Pocket and on joining the Backs. First, let's look at the Pocket.

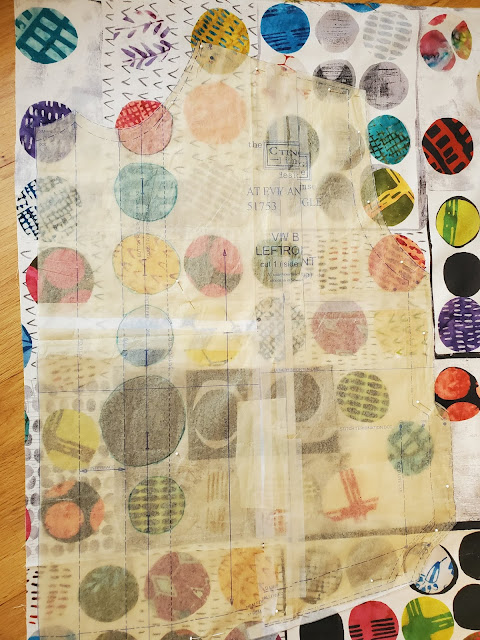

As you may remember, I laid the Pocket pattern on top of the stacked Right Front pattern piece on the Right Front fabric piece and drew the motifs on the Pocket pattern. Then I matched the drawn circles to the appropriate circles on the fabric and cut the Pocket. Here's a photo illustrating the result:

So now it's time to prepare the Pocket. In accordance with the instructions, interface the top facing, serge the top edge, press it down into place, and topstitch across it next to the serging. Staysitch down both sides of the Pocket and across the bottom at 3/8".

Using a Pressing Template, press the bottom of the Pocket first. This helps avoid any little "pokies" inadvertently peeking out from the bottom of the finished Pocket. Then press the sides at 3/8". Lay strips of Steam-a-Seam on the 3 edges of the Pocket, press gently, and remove the paper backing. Here's a photo of the Pocket when it's fully prepared.

All the info I just mentioned is in the instructions. I'd like to say a couple more things about our technique. You'll see 1 dot on the Pocket pattern. It should be placed on the matching dot on the Right Front. (Most patterns show 2 dots, but if either dot is marked incorrectly, the Pocket can be crooked. Also, it's easy to get just a bit off-grain when marking those 2 dots.)

Once you've matched that dot, you can measure from the side of the Pocket to center front from the top to the bottom of the Pocket to be sure it is placed correctly on the Front. The Steam-a-Seam makes it easy: it's slightly "sticky" so it will stay where you put it, but its position can be corrected. That's really useful if you're using a solid fabric or a different sort of print. Of course, my Pocket is being matched to the motifs underneath. So I placed it carefully to ensure the matching and pressed it in place. Now it can be stitched perfectly.

Of course the instructions show a "map" of the Pocket stitching. Again, I used the blind hem foot to stitch right on the Pocket edge. I began where the previous line of topstitching intersects the side of the Pocket. The top of the Pocket is toward me and I'm stitching to a point 3/8" in from the top corner (marked by a pin).

At the top edge, I pivoted to stitch across the top corner (anchoring the 3/8" seam allowance underneath--use a pin to tuck away any bits that may be sticking out before stitching). Count your stitches to the corner. Pivot again to stitch down the side and on around the Pocket to the other corner.

At the final corner, pivot to stitch across, again making sure the 3/8" folded edges are tucked away, and stitch the same number of stitches you used on the first corner. Finally, stitch diagonally to mirror image what you did on the first corner.

Ta-da! A perfect pocket.

Now we move to the Backs. Prepare them in the same way as the Fronts. Serge the side seam edges, staystitch the hem and vent at 1/4", press the 1/4" to the wrong side. Stitch the miters and press the vent and hem at 1". (If you missed this info, see my previous blog from June 4.) Finally, cut a 4" piece of Steam-a-Seam and slide it under the Left Back hem, starting at center back. Press, remove the paper backing, and fuse.

Now a really cool thing can happen. Normally, the Backs would be pinned and stitched as usual. But this time, I have cut my fabric to match the motifs down center back where the seam is. So I used a different technique.

First, I pressed the 5/8" center back seam allowance on the Right Back to the wrong side.

Then I placed Steam-a-Seam on the seam allowance next to the fold down to the dot marking Left Back hem.

Once I've pressed lightly and removed the paper backing, I can lay the Right Back on top of the Left Back and match the motifs just as I did on the Pocket.

Once all the motifs were perfectly matched, I pressed to fuse the Backs. Then I could turn back to the wrong side, Right Back on top of Left Back, prepared for stitching. The pin marks the dot at the Left Front hem, where I secured my stitching.

I have decided not to edgestitch and topstitch according to the instructions. I don't want rows of white stitching showing on my colored circles. I'll show you a different option when I am ready to finish the hems.